Rockdale Telecommunications facility – HVAC & Electrical Upgrade

Rockdale TE Level 1 Air Conditioning Upgrade

Ryan Wilks completed the major air conditioning upgrade at Rockdale exchange to accommodate the new NBN fitout.

The existing near vacant first floor equipment room was converted into a dedicated NBN area and as a well as the installation of typical high level ductwork and droppers included the installation of a dedicated 130 KW capacity air conditioning plant on the floor within the equipment area. The new plant install also provided space and fixtures to accommodate a fourth future air conditioning unit.

Like most projects access to the site was a big problem. At Rockdale this was complicated due to the proximity of adjacent building site and caryard located in front of the building and the concurrent Substation upgrade works which required the side lane to be closed off. This resulted in negotiations and co-ordination with the neighbours to enable deliveries, cranes and boom lifts to be set up and operated.

PROJECT HIGHLIGHTS

Due to tight NBN requirements the works were carried out in two stages to meet NBN roll out milestones. Stage 1 involve minor building works to demolish the existing toilet and change room on level 1 in preparation for the future air conditioning plant and the installation of the main ductwork.

The duct install consisted of two large cold aisle duct runs and one common return air duct all at high level hard up to the underside of the ceiling with sheetmetal droppers to the grilles located in the superstructure below. The ductwork was temporarily connected to the existing base building systems to provide air conditioning for the initial NBN fitout

Stage 2 involved the installation of the new air conditioning plant.

To provide fresh air for the new air conditioning plant the existing level 1 windows had to be removed and replaced with fire dampers (BCA requirement) and weatherproof louvers.

The fire dampers posed design issues with respect to access for ongoing annual inspection. This problem was simply resolved by installing motorised dampers on hinges with dolly wheels supports that allowed the dampers to swing open and provide access to the dampers for testing. A classic “engineered” solution to a common access problem.

Along the eastern façade a new 4 m tall cool room “sandwich” panel outside air / return, air mixing plenum was created from floor to ceiling. The use of the cool room panel offered a number of benefits in that it is durable, is lightweight, provides a very neat neutral white finished product and most importantly provided very minimal mess and debris during within the operational equipment room. With most panels being cut to size in the factory and delivered to site ready to install, only minor site cutting was required for final positioning of grilles. The styrene beads were much easier to control and clean up rather than conventional products such as gyprock. Whilst this product provided thermal insulation the internal walls of the plenum were lined with acoustic insulation to reduce the noise generated by the operating plant. In addition to the acoustic benefits this insulation also provides cover to “hide” the myriad of conduits and cables required to operate the plant which were all run within the plenum where possible.

In addition to the high level return air duct there are two large floor level return grilles fitted into the floor to ceiling return air plenum.

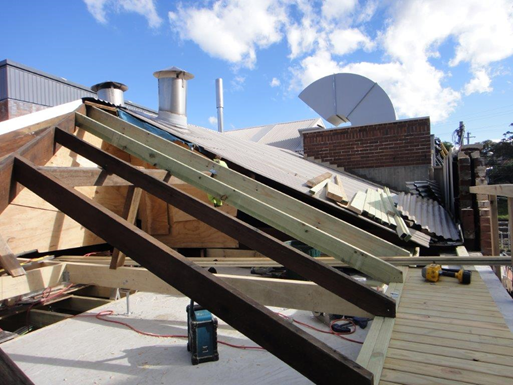

The new plant comprises 3 Temperzone split type package units located on the floor with condensers located on the tower roof area above. Due to the limited space available, two of the units were installed piggy backed one on top of the other.

As we indicated earlier the installation included provision for a future fourth air conditioning unit. The ductwork system and the relief air fan (15,760l/s) system have been designed to accommodate a future 200 Kw load. The preparation works such as a plinth and filter plenum have been installed. This installation provides for NBN requirement now and the future.

Rockdale TE Sub Station Construction

These works included the construction of a sub station to accommodate the additional electrical load to service NBN equipment. The project involved major building works and resulted in the demolition of the front corner of the building, excavation of new sub station pits and the construction of the new sub station and then re-building the old façade to match the existing. The front section of the building also housed the existing site generator which had to be de-commissioned and removed.

To over access problems co-ordination was sort between council and the RTA to enable the lane way to be closed off for two fixed periods and a traffic management plan implemented so not to impact on deliveries and pick up to the adjacent shopping centre. Sounds simple but the project involved a lot of hard work from all involved. The works were also undertaken concurrently with the Level 1 NBN upgrade and the construction of new generator room.

An NBN project manager commented during an inspection that ” this project should be used as an example of the quality of installation that we should be seeking on all our projects “. Kind words and appreciated by all associated with the project.

They say a picture worth a thousand words, here are the works from start to finish!