Keepit Dam Electrical Upgrade

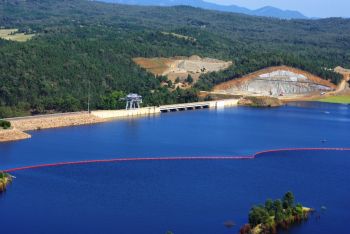

Keepit Dam is a Major Gated Dam located 56 kilometres West of Tamworth on the Namoi River in the Namoi Valley. The Dam has a storage capacity 425,510 mega litres, surface capacity of 4,370 hectares and is primarily used for Environmental, Hydro-power, Irrigation, stock, domestic, town water, water conservation and of course recreational purposes.

Keepit Dam was completed in 1960, following a 21-year construction, delayed by World War 2. Due to the age of electrical infrastructure and a re-evaluation of the dam’s effectiveness when faced with a maximum flood level, Ryan Wilks was engaged to upgrade the entire electrical reticulation system as Stage 2 of a total Dam safety infrastructure upgrade. The upgrade of the Dam received a lot of public interest throughout the development application stage and the State Government were keen to see that this job went to plan, hence the project received some media coverage from both the local newspaper and the TV station, something that Ryan Wilks personnel handle very well.

Ryan Wilks where able to successfully complete this welcomed challenge to improve the Dam’s essential infrastructure and ability to provide continued safety to the surrounding community, which incorporated the following works.

PROJECT HIGHLIGHTS

The High Voltage Reticulation

- Installation of a privately metered underground High Voltage reticulation throughout out the site incorporating innovation to the original design to improve the clients serviceability needs

- Evaluation and design of the HV and LV earthing requirements with innovations incorporating Isolation transformers and the earthing installation

- Supply and installation of a Ring Main Unit

- Relocation and modification to an existing transformer to meet the clients safety and serviceability needs

The Low Voltage Reticulation

T1 Installation

The first and largest portion of the reticulation is located at T1 and involved the installation of a new main switchboard to supply the surrounding workshops, the Dam wall and the auxiliary supply to the onsite Hydro Electric Power Station. This install also included a 275kva standby backup generator incorporating Ryan Wilks fuel design, provision for the connection of a secondary onsite mobile generator, Power factor correction equipment and installation of all underground services.

T2 Installation

The second portion of the of the reticulation involved the relocation of an existing 200kva transformer to supply the onsite staff housing and offices, this location also incorporated provision for a back up mobile generator supply from the onsite mobile generator with a fast implementation time for continued reliability.

Dam Wall

The dam wall required additional attention to detail for its reticulation to ensure that the reliability is maintained at all times. This included scour protection for all incoming power, communication and control cabling, generator backup supply from T1, mobile generator backup supply from T1 and mobile generator backup supply at the new Dam wall main distribution board. These works also involved replacement of all electrical services in the top gallery to make way for the post tensioning in stage 3, wall raising in stage 4 and provision for the gate operation supplies.

Building works

As part of the upgrade, Ryan Wilks where intrusted with the design and construction of the new T1 Building to incorporate the new T1 Main Switch room, Generator room, bulk fuel storage, Pad mount substation and communication and control equipment. The building was designed and installed above the maximum flood tail water height and co-ordinated for enhanced functionality and safety. Ryan Wilks also installed mechanical scour protection.

Communication and control

The installation required Ryan Wilks to install and commission a new fibre Optic back bone network throughout the site incorporating a new corporate communication network and equipment, and a new control network and equipment.

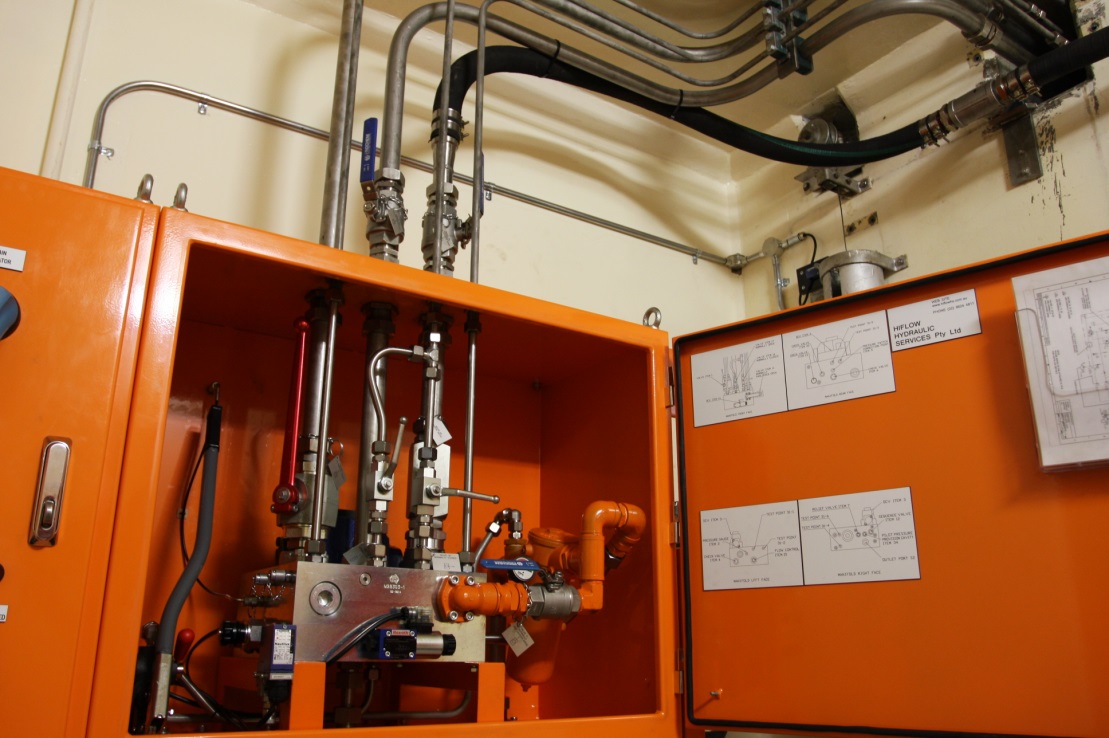

Hydraulic works

As part of the upgrade, Ryan Wilks successfully completed the replacement of the complete Hydraulic power systems required to open and close the emergency gate for the Hydro Electric Power station, incorporating remote control for inhanced safety. These works were completed safely over the dam water thanks to the implementation of a strict environmental management plan and a conscientious team.

Result

Ryan Wilks project team where able to revel in the challenges the Keepit Dam Stage 2 upgrade project brought to the table. The project was able to be successfully completed to a high standard of quality, was on time and within budget. This project was another great example of Ryan Wilks ability to manage a challenging project without compromising safety or impacting on to the environment.

Value $2,150,355.00.

[MW1]SCADA removed from Scope