Lakemba Telecommunications facility – 279Kva SGP Upgrade

The new 400KVA Cummins generator installation was to upgrade an existing 200KVA set that had recently failed catastrophically. A temporary mobile generator supported the building with standby power until the completion of the project.

PROJECT HIGHLIGHTS

The demolition works included the complete gutting of the existing generator and adjacent air conditioning plant room, the removal of the existing 200Kva SGP, remote radiator & pipe work, exhaust flue, fuel system, exhaust silencer and sub-mains cabling and associated Generator Control. The existing compact generator room was made larger by knocking walls down to the adjacent redundant air conditioning plantroom. This made room for the new generator intake and discharge ventilation air and associated noise attenuation ductwork.

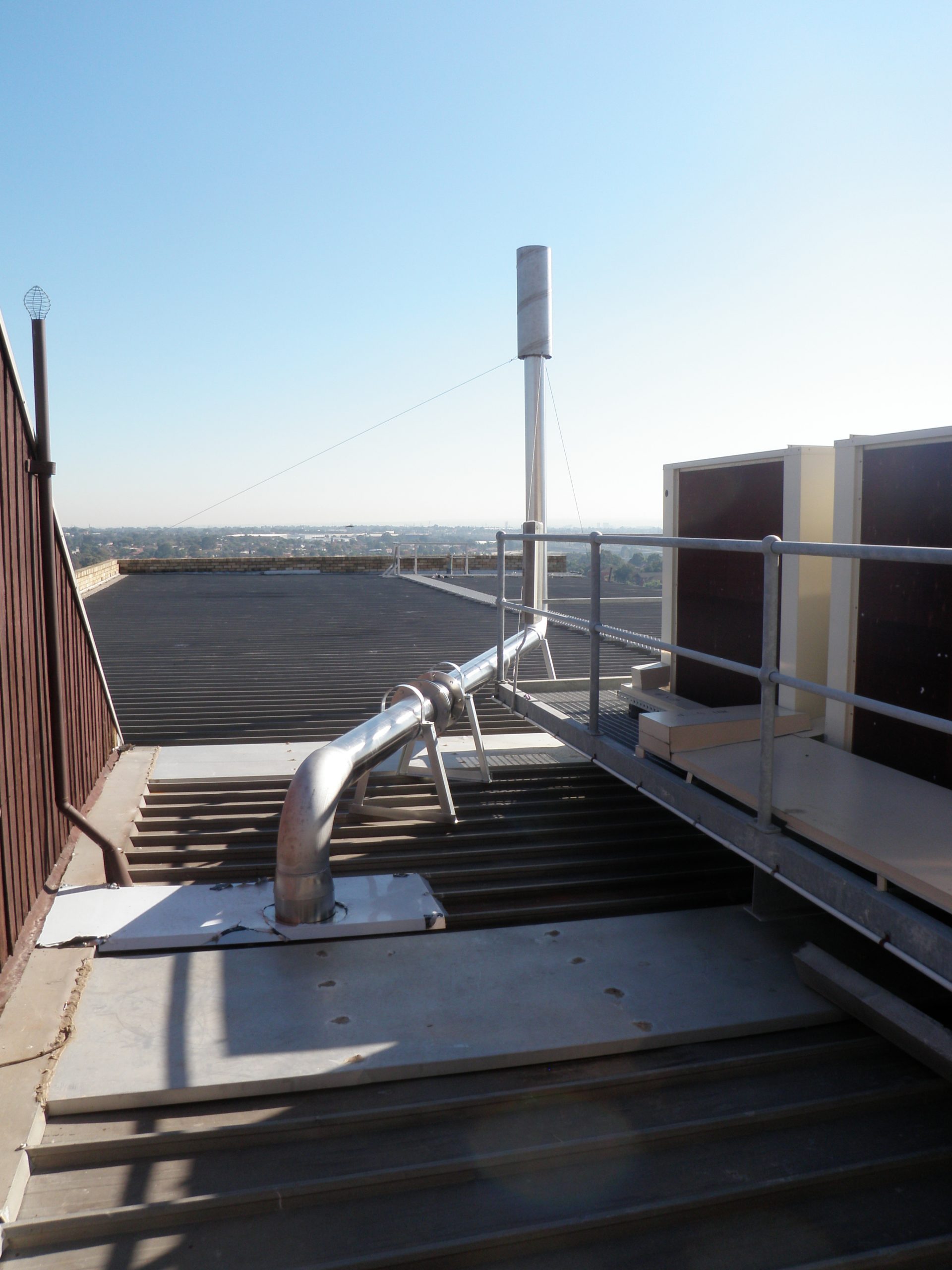

The existing mild steel exhaust flue ran from ground level up six floor to the roof and was removed to make way for the installation of a new stainless flue which required comprehensive work strategies and procedures to conduct the works in a safe and productive manner.

The new fuel system was designed to utilized the existing underground bulk fuel tanks. The new system incorporated a new diesel day tank within the generator room, because the existing bulk fuel tanks where located above the day tanks an overflow pump and controls where required to transfer overflow fuel to the bulk storage tank.

Fire rating works included 120/120/120 FRL fire rating of exhaust flue riser and existing redundant air conditioning ductwork within the ceiling slab. All structural steel members supporting the air duct penetration were also fire rated.

The new Generator was commissioned and pre-start checks carried out over a 5 hour dummy testing period. The 4 x 1c x 300mm² fire rated generator cabling ran to the existing MSB and was cut over during controlled out-of-hours cutover works. The new system was proven to operate under full building load and control time and sequencing specifications. Successful acoustic analysis of the installation completed the commissioning process.

Overall the project was completed on time and budget with no OH&S incidents – largely due to a committed and experienced work force who were keen to move onto the more vibrant surrounds of a Paddington Project.

Value $ 230k