Telecommunication Satellite Facility Adelaide – UPS Capacity Upgrade

Ryan Wilks completed the full electrical and mechanical design & construction of this Uninterrupted Power System at a critical site in Adelaide. The project was completed remotely from the Sydney branch during the height of the COVID-19 Global Pandemic and associated national and international border travel restrictions, with practical completion and final load migration completed ahead of schedule.

The new UPS system has been installed in a vacant old EPG Room. This vacant room enabled the installation and commissioning of the new system ahead of the load migration of all final new and existing and associated critical business loads.

High praise was received from this global telecommunications provider for the team’s positivity and quality project delivery during these difficult pandemic times.

Building Works Summary

- The relocation of storage spares and storage racking from the old generator plant room

- FRL of 120/120/120 fire rating of the external walls to achieve fire separation under the DTS provisions of the BCA for this new battery and power room.

- Replacement of existing external door with a fire rated door and frame to achieve a fire rating of -/120/30.

- To achieve compliance with C2.12 all new penetrations through fire rated walls have been suitably treated, using tested systems to maintain the existing 120/120/120 fire separation.

Fire Detection Summary

Given the criticality of the facility, the building requires fire detection throughout. As the system is monitored by the fire brigade, full coverage to AS1670.1 is maintained as part of the SAMFS conditions of connection. On this basis the following works were completed:

- Decommissioning of the existing pre-action sprinkler system within the old generator plant room.

- Supply, installation and commissioning of new VESDA aspirated detection system within the UPS room compliant with AS1670.1.

- Updating fire alarm block plans to suit the new and decommissioned system.

Mechanical Summary

- Design and installation of new UPS Room cooling system and the supply of 2 x Liebert PCW PH025 Chilled Water Cooled CRAC Units (PCW). These are downflow units which provide direct cooling to the UPS system and ambient cooling in the UPS room.

- Chilled water modification works.

- Battery room exhaust ventilation.

- Full load and site acceptance testing of the cooling and ventilation system.

Electrical Summary

- A full site survey of the sites electrical instruction and reticulation enabling the procurement of an overall up-to-date site Single Line Drawing.

- Planned Main Switch Board shut down to complete the installation of four (4) off new 630 Amp MCCBs.

- Planned shutdown of the Generator Main Switch Board to install a new extension cubicle housing (4) off new UPS overall bypass 630 Amp MCCBs:

- Unintrusive hydro excavation and installation of underground 6 x 150mm Conduits and associated UPS bypass mains cabling.

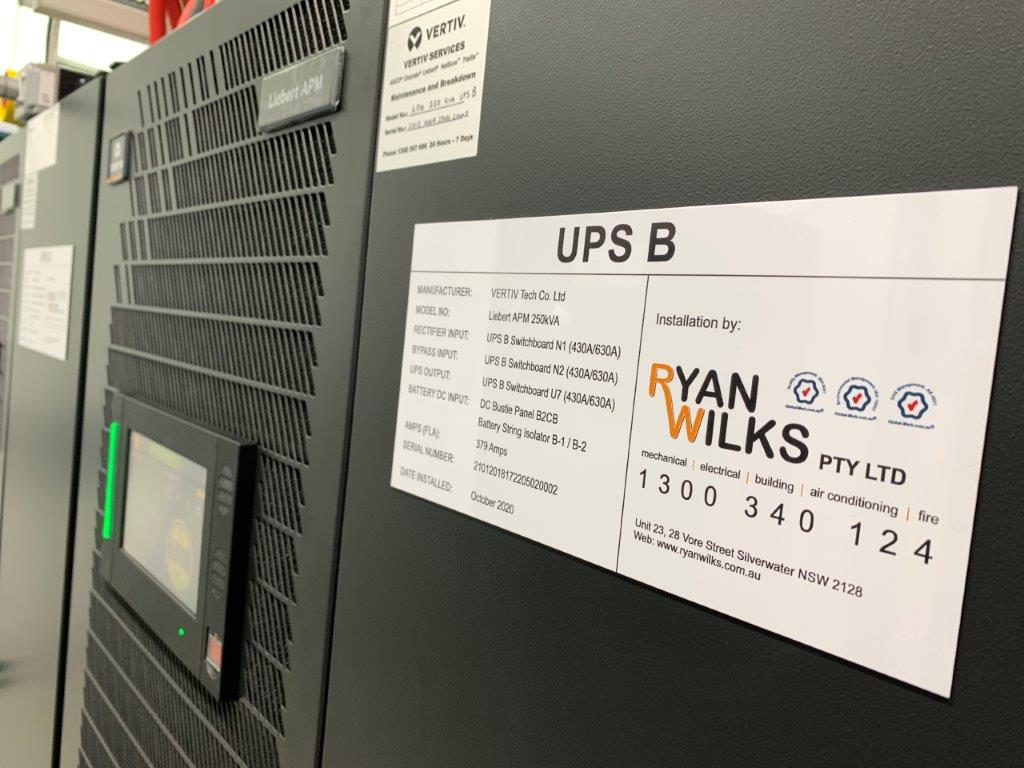

- Supply and installation of 2 x Vertiv Liebert APM 250kVA UPS’s complete with battery strings and battery racks (2 strings per UPS), site acceptance testing including dummy load testing and 2 hour soak test on both UPS EPG and UPS Normal Supplies.

- Supply and installation a new DC Bustie Switch Board, UPS A and UPS B Input / Output Switch Boards, UPS A and UPS B Overall Bypass Switch Boards, two additional 400Amp UPS Distribution Boards.

- Supply and installation of BMS Alarms and Monitoring for the new UPS Systems.

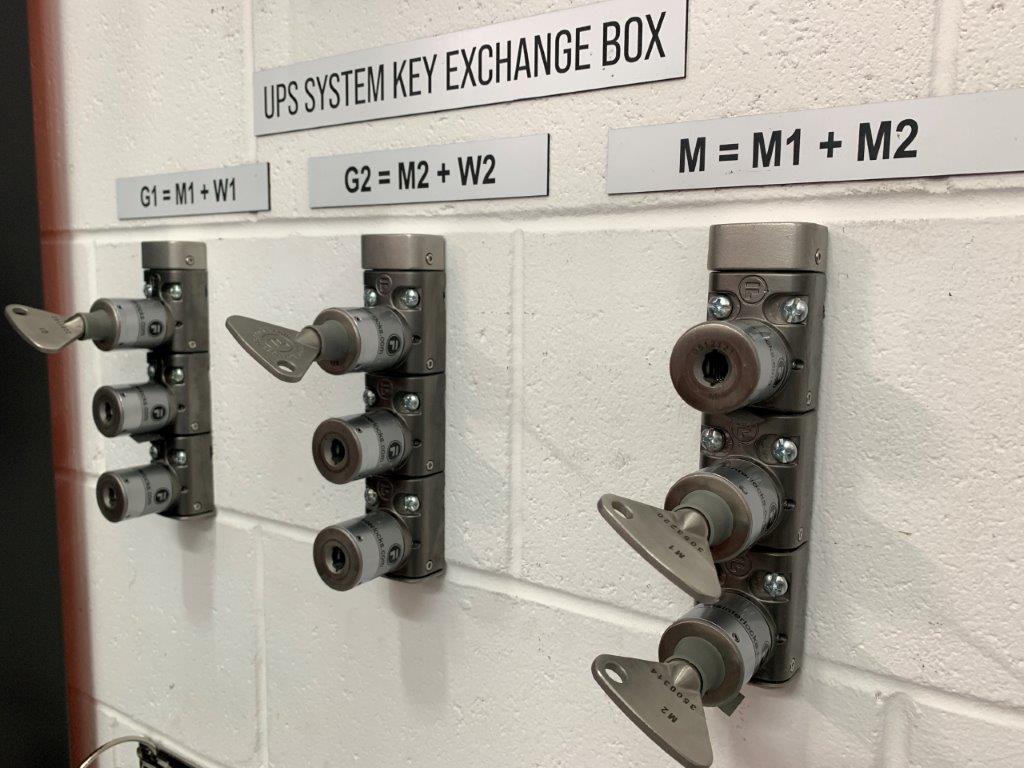

- Design and installation of the UPS System Castel Key Interlocking System.

- Modification to the existing MSB ATS controls to incorporate UPS System On Battery EPG Start signal / ATS inhibit control modification the to the MSB ATS.

- Demolition and making good the existing 2 x 80 kVA Vertiv UPS system, batteries, and associated UPS switchboards